In today's hyper-aggressive world wide market place, companies are constantly trying to get techniques to boost efficiency, cut down expenditures, and retain the highest levels of quality. standard ways of good quality Regulate tend to be time-consuming and prone to human mistake. This is where vision measurement machine suppliers are stepping in with impressive methods which are revolutionizing production procedures. This article will delve into how Innovative vision measurement technological know-how, specifically specializing in Easson's cutting-edge 3-axis CMM machines, is not merely Assembly present demands, but actively long run-proofing your complete production field.

Table of contents:

AI Integration and Automation: the following Frontier in Measurement

actual-Time knowledge Investigation: Minimizing Downtime, Maximizing Output

Easson’s 3-Axis CMM: primary the cost in Scalability and Adaptability

AI Integration and Automation: The Next Frontier in Measurement

The mixing of synthetic Intelligence (AI) and automation is no more a futuristic idea; it’s a current-day reality drastically enhancing the capabilities on the eyesight measurement equipment. AI algorithms empower these devices to master from wide datasets, autonomously enhance measurement parameters, and recognize even one of the most refined defects with unparalleled speed and accuracy. This interprets to a big reduction in human intervention, reducing the chance of faults and accelerating inspection instances. Automated managing programs further streamline functions by seamlessly incorporating measurement processes into the present manufacturing line, causing a extremely productive and optimized workflow. The enhanced throughput enables suppliers to meet demanding output schedules devoid of compromising excellent.

Real-Time knowledge Assessment: reducing Downtime, Maximizing Output

serious-time knowledge Assessment is proving for being a pivotal Device for companies striving to minimize expensive production downtime. present day eyesight measurement units are actually Outfitted with strong application platforms able to giving speedy and actionable feedback on essential Proportions, tolerances, and method versions. This instantaneous details stream enables proactive identification of possible issues, including untimely Software wear, equipment calibration deviations, or substance inconsistencies, extended in advance of they escalate into important defects or catastrophic generation stoppages. By leveraging this actual-time intelligence, brands can put into practice rapid corrective actions, improve system parameters, and ultimately guarantee constant, uninterrupted generation whilst reducing squandered resources and scrap product.

Easson’s 3-Axis CMM: primary the demand in Scalability and Adaptability

Easson's 3-axis CMM (Coordinate Measuring device) equipment are for the vanguard of vision measurement technologies, presenting unparalleled scalability and adaptability to meet the evolving requires of recent production. These machines are meticulously engineered to support a diverse number of component measurements, intricate geometries, and varying substance forms, generating them ideally suited to a broad spectrum of manufacturing apps, from aerospace to automotive. As detailed on https://zh-easson.com/products/visual-video-cmm-measurement-machine-with-3-axis-001%CE%BCm-linear-encoder, Easson's machines are renowned for their Excellent precision, boasting impressive 0.001μm linear encoders, guaranteeing the very best achievable volume of precision and repeatability. Their modular layout facilitates seamless updates and customizations, making it possible for manufacturers to adapt swiftly to shifting manufacturing demands and technological improvements with no incurring significant cash expenditure. Additionally, Easson's unwavering motivation to consumer-friendly computer software interfaces and complete schooling applications makes sure a seamless integration process and optimum utilization in their State-of-the-art technologies, empowering operators To maximise the equipment’s likely.

In summary, vision measurement technological know-how signifies way over just a sophisticated high-quality Command Instrument; It's really a strategic imperative for companies seeking to upcoming-evidence their operations and maintain a competitive edge in today's demanding market place. By embracing the power of AI integration, genuine-time info analysis, and hugely scalable remedies like Easson's Highly developed 3-axis CMM devices, suppliers can realize unprecedented levels of precision, greatly cut down downtime, improve output performance, and finally push sizeable enhancements in profitability. The strategic expense Within this transformative technological innovation is not really merely an option but a requirement for long-term good results. go ahead and take proactive action to explore how State-of-the-art eyesight measurement methods can empower your small business to prosper while in the ever-evolving production landscape, and reach out to your trustworthy vision measurement machine provider to discuss your specific more info requirements and necessities nowadays.

Michael Oliver Then & Now!

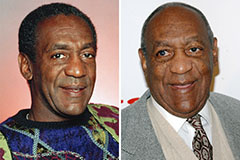

Michael Oliver Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!